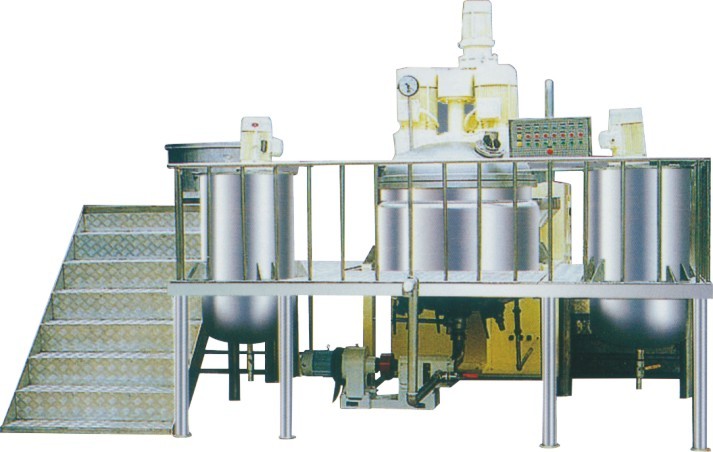

High speed ceramic ultrafine homogenizer emulsifier

The high-speed ceramic ultrafine homogenizer emulsifier adopts the principle of seamless high-speed shear to uniformly refine the material, with a particle size of 0.5 μ. This equipment is an upgraded version of the refining industry. It is the flagship product of the wet refined market in the future.

Because the stator and rotor of the machine are embedded with high hardness special ceramic blades, it cuts and crushes materials at a cutting speed of over 1-2 million per minute. The unique fluid motion high design turns the material into ultrafine micron sized powder.

It has important implications for saving raw materials, reducing costs, and improving equipment quality. This device is particularly suitable for applications in pharmaceuticals, cosmetics, dyes, food, and other fields.

This device has almost no wear and tear in application, and can ensure accuracy even after long-term use. These advantages are incomparable to ordinary stainless steel homogenizers.

Our company can manufacture various machinery and equipment for production and laboratory use according to the requirements of manufacturers, including vertical, horizontal, pipeline, multi-stage and other flow and capacity units, to meet the requirements of various companies for wet high-precision crushing.

advantage

◆ Ultra high 050000CPS. The emulsion is thoroughly stirred and evenly mixed, and the diameter of the emulsified particles can reach 25 μ m. Vacuum suction, high production frequency, easy and reliable operation.

This machine can be used for heating, melting, vacuum, homogeneous cooling, and continuous operation.

Made entirely of stainless steel, with vacuum stirring for hygiene and sterility.

◆ Easy to clean.

The newly developed ceramic gland free high cutting homogenizer emulsifier can achieve a particle diameter of 0.5 μ m.

Main Technical Parameters