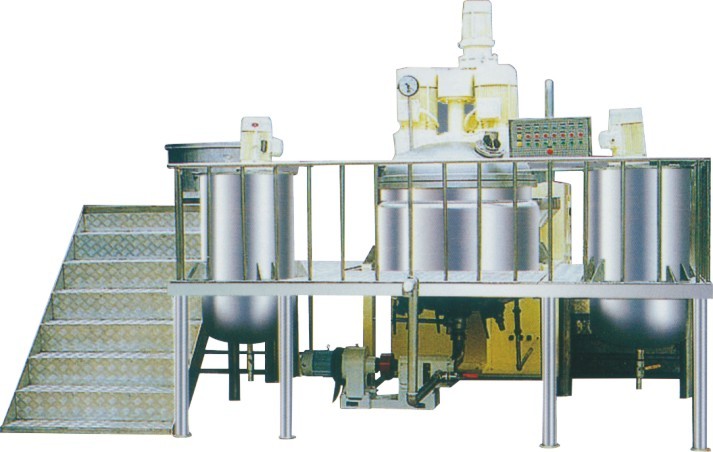

The main application of the hose nozzle machine is the injection molding production of the shoulder of the packaging hose. The B.GLS- model of the nozzle machine produced by our company has a fast production speed, a high degree of automation, stable performance, and no pollution in the production process. It can high benefits for a wide range of hose manufacturers and daily chemical product manufacturers.

Compared with other models at home and abroad, the fully automatic nozzle machine of our company the following advantages:

1. All the actions of this hose nozzle machine are PLC servo controlled, with low pneumatic requirements and stable operation.

2 Integrating water, electricity, and gas, the production efficiency is high, the energy consumption is low, the operation is simple, the fault is automatically alarmed, and there is three waste.

3. The full mold is used, the shoulder of the hose is seamless, the appearance is beautiful and solid.

4. The turntable and key parts are mainly made of manganese-magnesium alloy, which is light and stable, and is conducive to the long-term operation of the machine.

5. All the main parts of the machine are imported foreign accessories.

This hose nozzle machine mainly includes: clearance indexing mechanism, automatic feeding mechanism, quantitative extrusion mechanism mold closing mechanism, demoulding separation mechanism, automatic unloading mechanism, automatic feeding mechanism, buffer storage tank, etc.

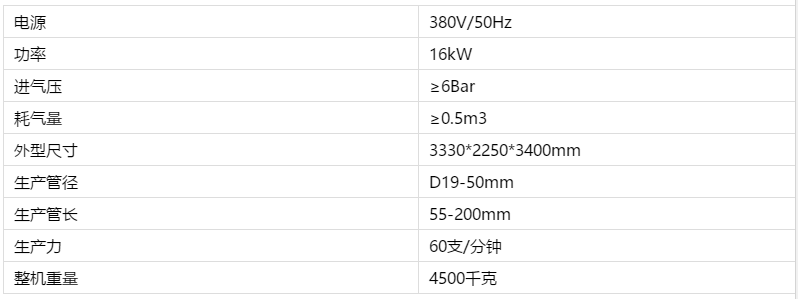

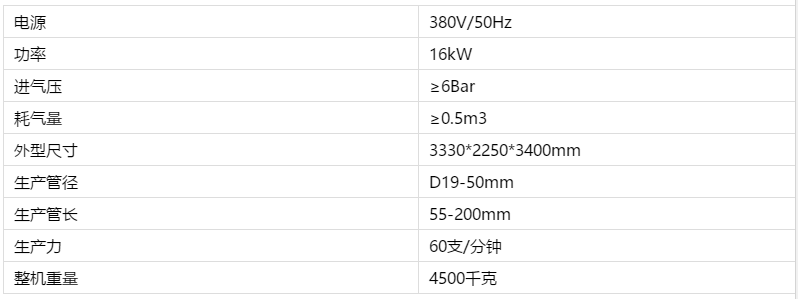

Main technical parameters