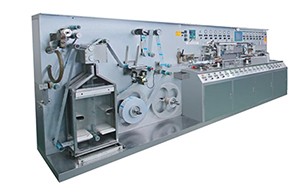

B.GLS-Ⅲ type composite soft tube making machine is designed and developed by our company on the basis of the second generation of tube machine and absorbing foreign advanced technology. The machine uses fuzzy control technology and integrates machine, electricity and gas. Compared with similar products at home and abroad, it has the characteristics of high, low energy consumption, easy operation, fault automatic alarm, no need to stop the machine when changing the roll of plate, accurate positioning of the rotating cutter, stable performance and convenient.

The equipment uses aluminum plastic composite plate, full plastic composite plate as raw materials, using high frequency and other welding technology, can manufacture all kinds of specifications and models of soft tubes. The products manufactured have straight and firm welds, accurate cutting, and consistent length and width.

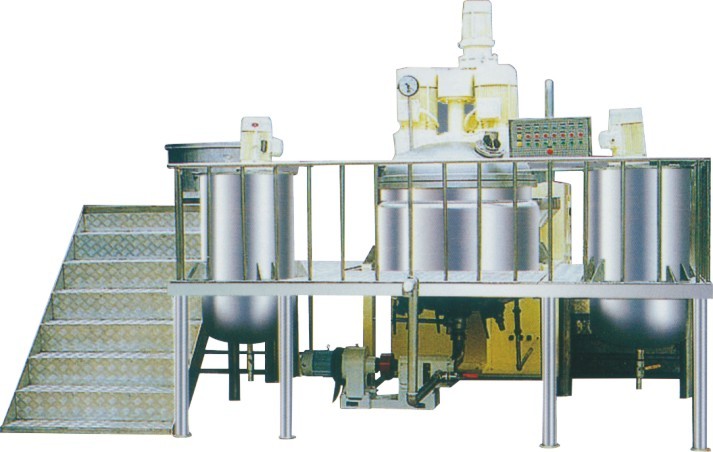

The equipment can be matched with the B.ZTIII type fully automatic shoulder injecting machine manufactured by our company to form a fully automatic tube making line.

The use of the non-stop roll changing device has the characteristics high utilization rate of plate and low labor intensity.

The main equipment of this unit includes: automatic unwinding device, butt joint platform, storage device, automatic edge cutting device automatic forming device, high frequency welding device, full plastic composite welding device, vertical and horizontal indexing device, automatic feeding device, automatic control tracking device and man-machine interface system control

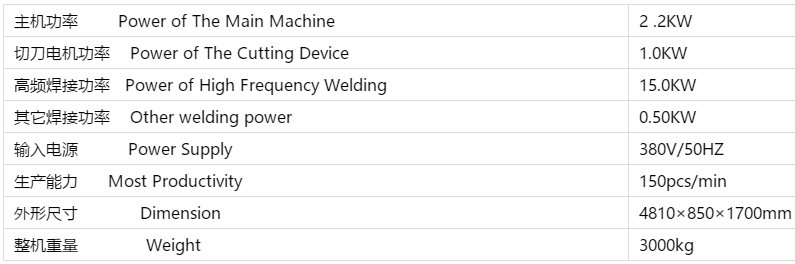

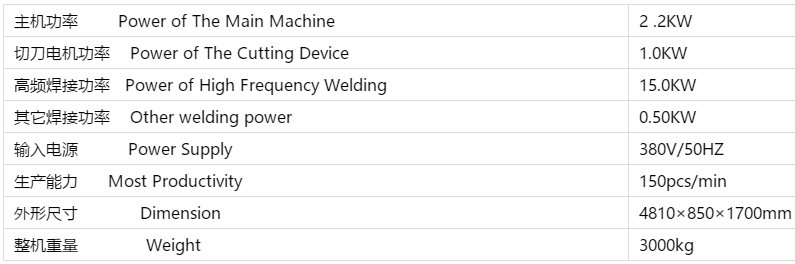

Main technical parameters